Bacon Engineering, Ltd.

Bacon Engineering, Ltd.Request A Quote

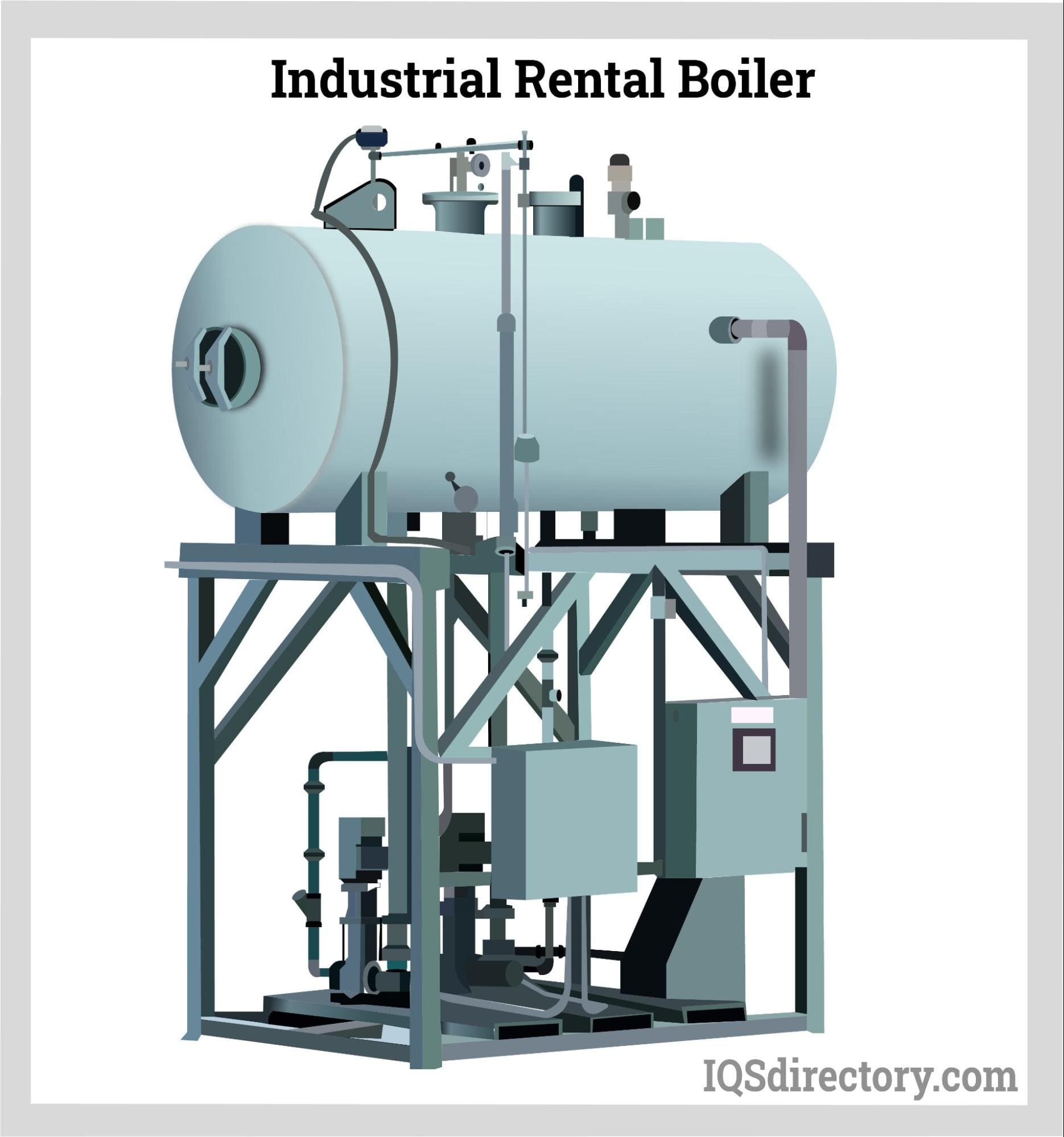

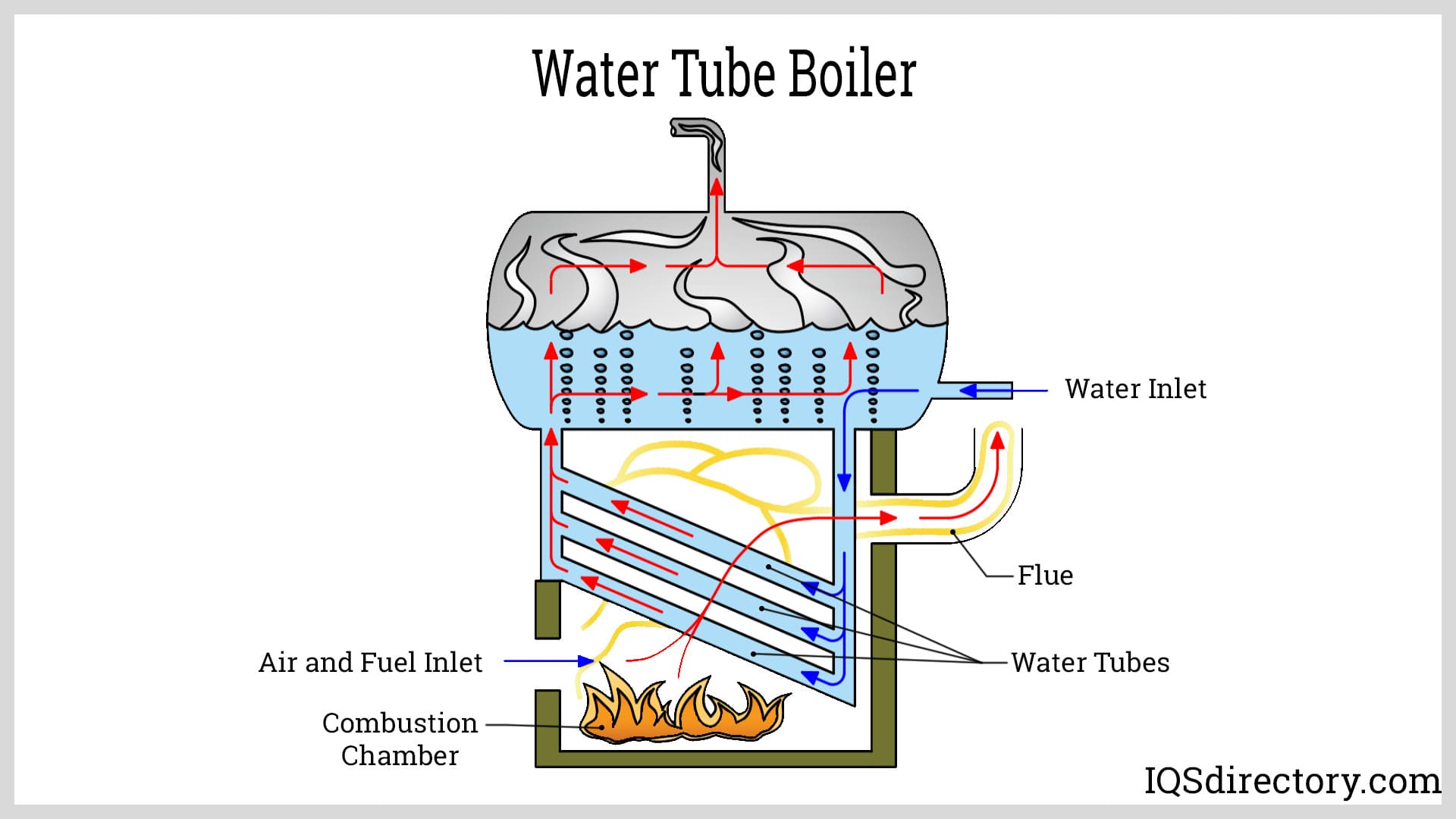

Toronto, ONBacon Engineering, Ltd. is a leading provider of industrial boilers and comprehensive solutions for a wide range of industries. With a strong commitment to innovation, quality, and customer satisfaction, Bacon Engineering has established itself as a trusted name in the industrial boiler industry. The company offers a diverse range of industrial boilers designed to meet the specific needs and requirements of different applications. Their product line includes firetube boilers, watertube boilers, packaged boilers, and more. These boilers are engineered with precision and built to the highest standards, incorporating advanced technologies and robust materials to ensure efficient and reliable operation. Bacon Engineering understands that each customer has unique heating and process requirements. Their team of experienced engineers and technicians work closely with clients to assess their needs, taking into account factors such as capacity, pressure, fuel options, and environmental considerations. By leveraging their expertise and industry knowledge, Bacon Engineering delivers customized boiler solutions that optimize performance, energy efficiency, and cost-effectiveness. In addition to providing high-quality industrial boilers, Bacon Engineering offers a comprehensive range of services to support their customers throughout the entire lifecycle of their boiler systems. Their team of skilled technicians provides professional installation services, ensuring that each boiler system is installed correctly and meets the highest safety standards. Bacon Engineering also offers maintenance and repair services to ensure the ongoing reliability and efficiency of their boiler systems. They provide regular inspections, cleaning, and servicing to optimize performance and minimize downtime. In the event of a breakdown or malfunction, their technicians are available to provide prompt and efficient repairs, ensuring minimal disruption to the customer's operations. The company places great importance on energy efficiency and environmental sustainability. Bacon Engineering incorporates advanced control systems and energy management solutions into their boiler systems to optimize fuel consumption and reduce emissions. They strive to help their customers achieve energy savings, comply with environmental regulations, and minimize their carbon footprint. Customer satisfaction is at the core of Bacon Engineering's business philosophy. They prioritize building long-term relationships with their clients by providing exceptional customer service and support. Their team of experts is available to offer technical assistance, troubleshooting, and training, ensuring that customers can operate their boiler systems efficiently and effectively. Bacon Engineering takes pride in their commitment to quality, safety, and reliability. They adhere to stringent industry standards and regulations to ensure that their products and services meet the highest quality benchmarks. Through continuous improvement and innovation, they stay at the forefront of the industry, offering cutting-edge solutions to meet the evolving needs of their customers. In summary, Bacon Engineering, Ltd. is a trusted provider of industrial boilers and comprehensive solutions. With their focus on innovation, quality, and customer satisfaction, they deliver reliable and efficient boiler systems that optimize performance, reduce operating costs, and comply with environmental regulations. By choosing Bacon Engineering, customers can expect top-notch products, expert service, and a reliable partner for their industrial boiler needs.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

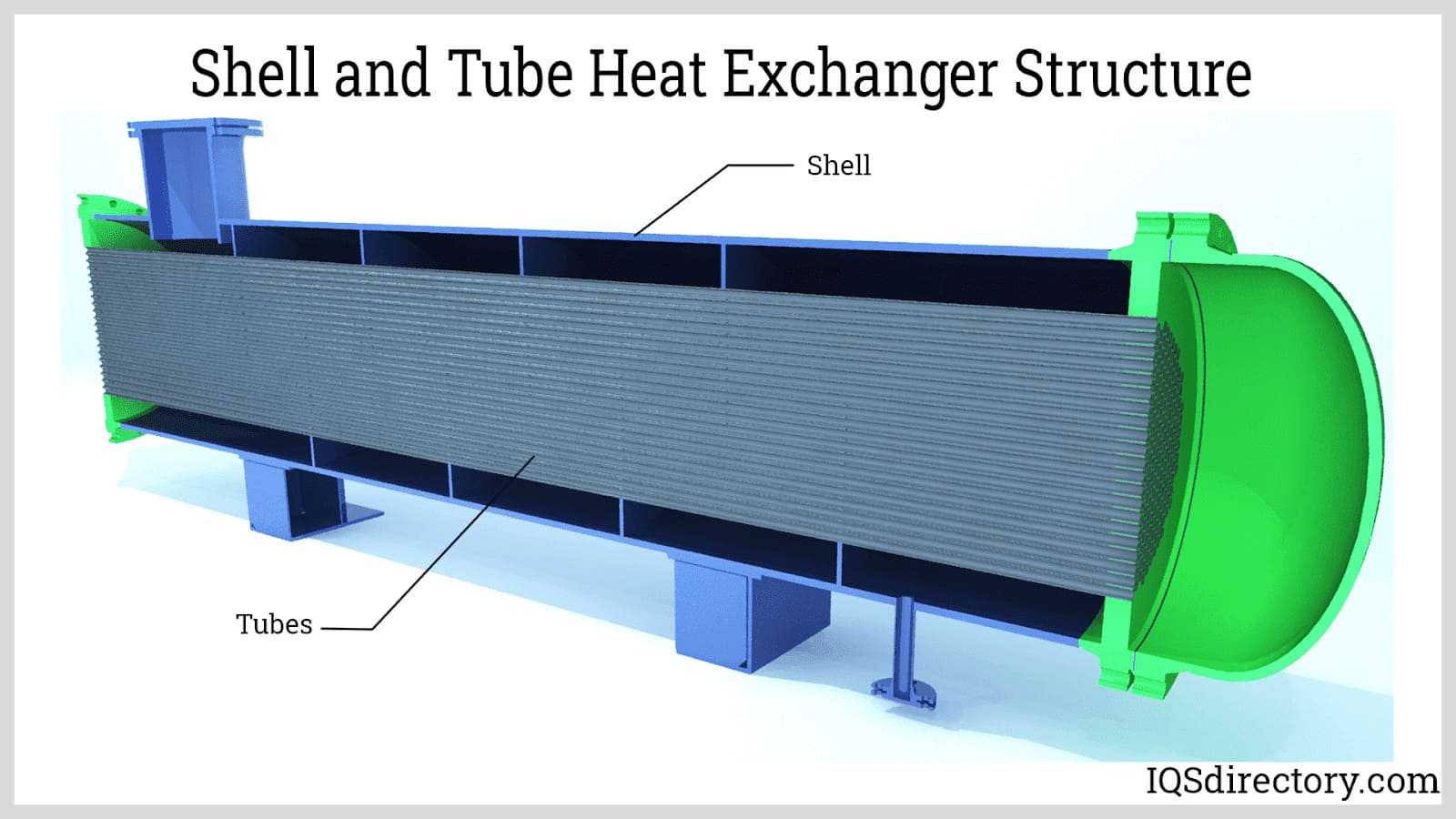

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services