Acme Engineering Products

Acme Engineering ProductsRequest A Quote

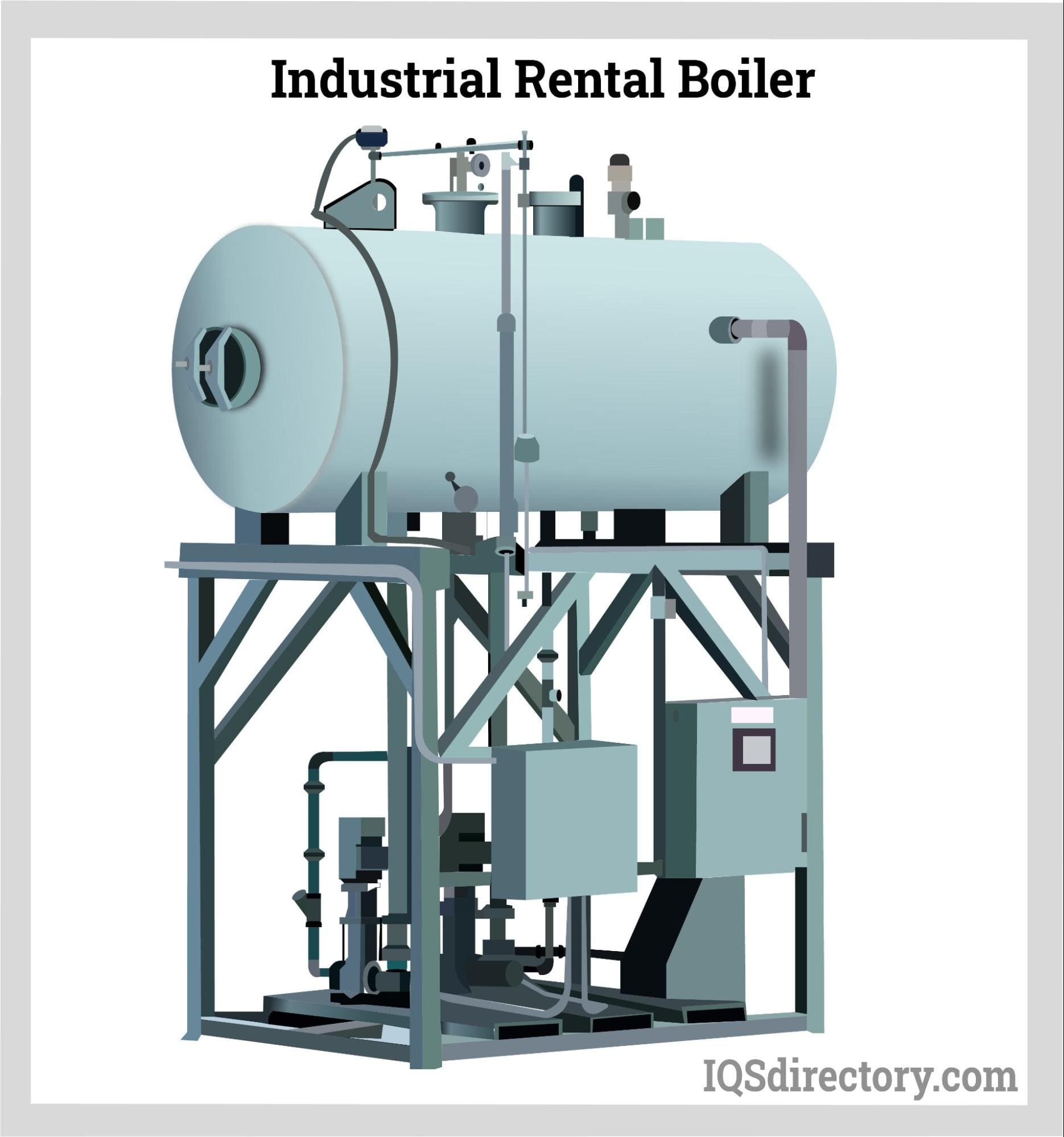

Montreal, QCAcme Engineering Products is a renowned provider of industrial boilers, offering a wide range of innovative products and exceptional service capabilities. With a rich history spanning several decades, Acme Engineering has established itself as a trusted name in the industry, delivering reliable and efficient boiler solutions to various sectors. Acme Engineering's industrial boilers are designed and manufactured to meet the diverse needs and demands of industrial applications. They offer a comprehensive range of boiler types, including electric boilers, gas-fired boilers, oil-fired boilers, and biomass boilers. These boilers are engineered with cutting-edge technologies and high-quality components to ensure optimal performance, energy efficiency, and long-term reliability. One of the key focuses of Acme Engineering is energy efficiency. They strive to develop boiler solutions that minimize energy consumption and reduce environmental impact. Their boilers incorporate advanced combustion systems, heat recovery technologies, and intelligent controls to maximize fuel efficiency and minimize emissions. By prioritizing energy efficiency, Acme Engineering helps their customers achieve significant cost savings while contributing to a greener and more sustainable future. In addition to their exceptional product offerings, Acme Engineering provides a comprehensive suite of services to support customers throughout the entire lifecycle of their boilers. Their team of highly skilled engineers, technicians, and service professionals offers a wide range of services, including installation, commissioning, start-up assistance, maintenance, and repairs. They have extensive knowledge and expertise in boiler systems, allowing them to deliver customized solutions that meet specific requirements. Acme Engineering understands the importance of proactive maintenance in ensuring the optimal performance and longevity of industrial boilers. They offer tailored maintenance programs that include regular inspections, cleaning, efficiency checks, and component replacements. These programs are designed to prevent issues, identify potential problems early on, and extend the lifespan of the boilers. By investing in regular maintenance, customers can minimize downtime, maximize productivity, and enhance safety. In the event of a service emergency, Acme Engineering's dedicated service team is available 24/7 to provide prompt assistance. Their technicians are well-equipped with the necessary skills, tools, and resources to diagnose and resolve issues efficiently. Acme Engineering values customer satisfaction and strives to minimize downtime, ensuring that operations can resume quickly and smoothly. Safety is a top priority at Acme Engineering. They adhere to the highest industry standards and regulations to ensure that their boilers are designed, installed, and maintained with a strong emphasis on safety. The company invests in ongoing training and certification programs to keep their team up-to-date with the latest safety practices and technologies, ensuring a secure working environment for both their employees and customers. Acme Engineering's commitment to customer success is evident in their customer-centric approach. They take the time to understand their customers' unique requirements, challenges, and goals, allowing them to provide tailored solutions that address specific needs. Their strong emphasis on collaboration and partnership ensures that customers receive exceptional value, reliable support, and unmatched customer service. In summary, Acme Engineering Products is a trusted provider of industrial boilers, offering a diverse range of high-quality products and exceptional service capabilities. With a focus on energy efficiency, sustainability, safety, and customer satisfaction, Acme Engineering is a preferred choice for industries seeking reliable and efficient boiler solutions. Their commitment to innovation, technical expertise, and dedication to customer success make them a leading player in the industrial boiler market.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

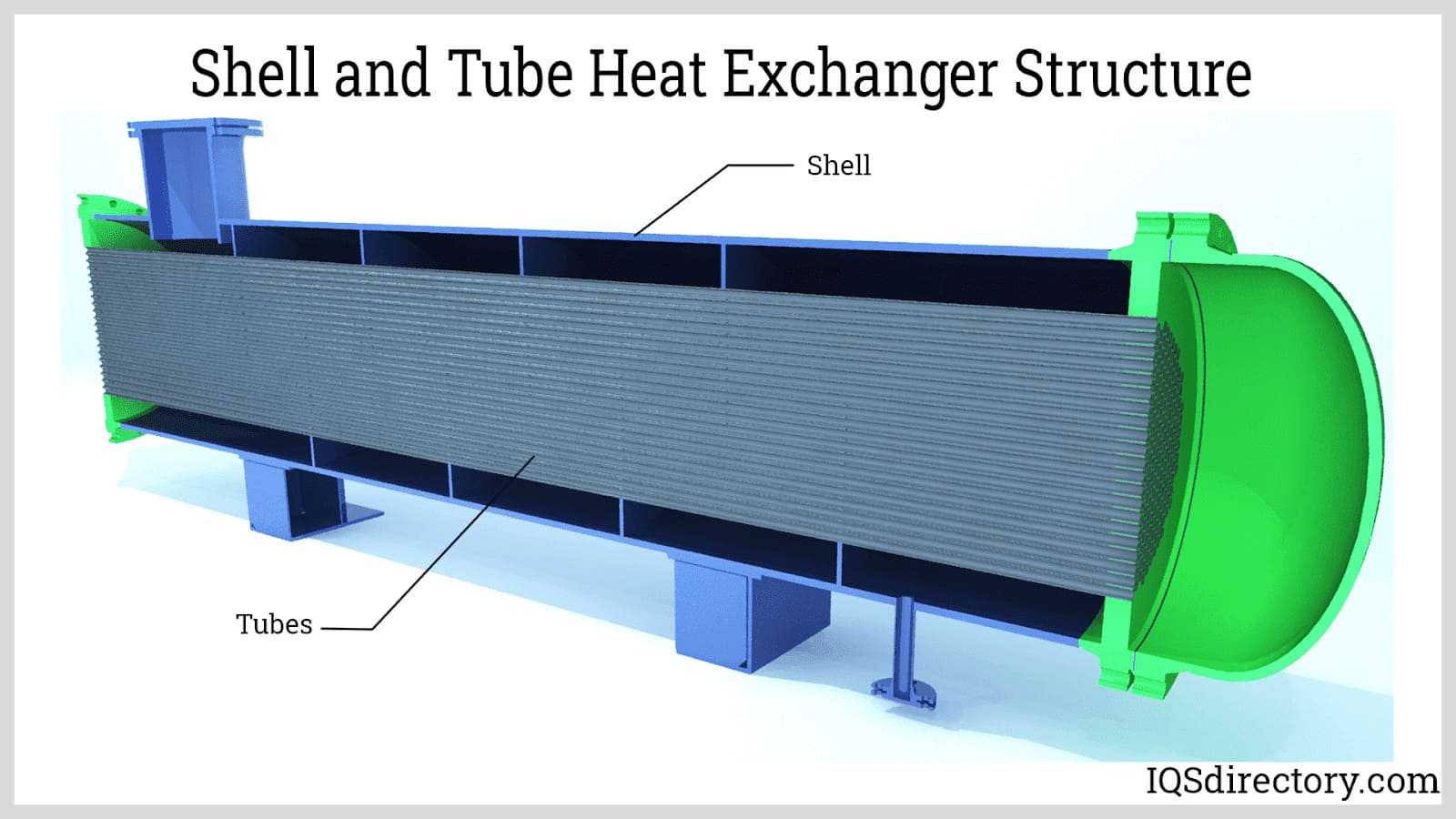

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services