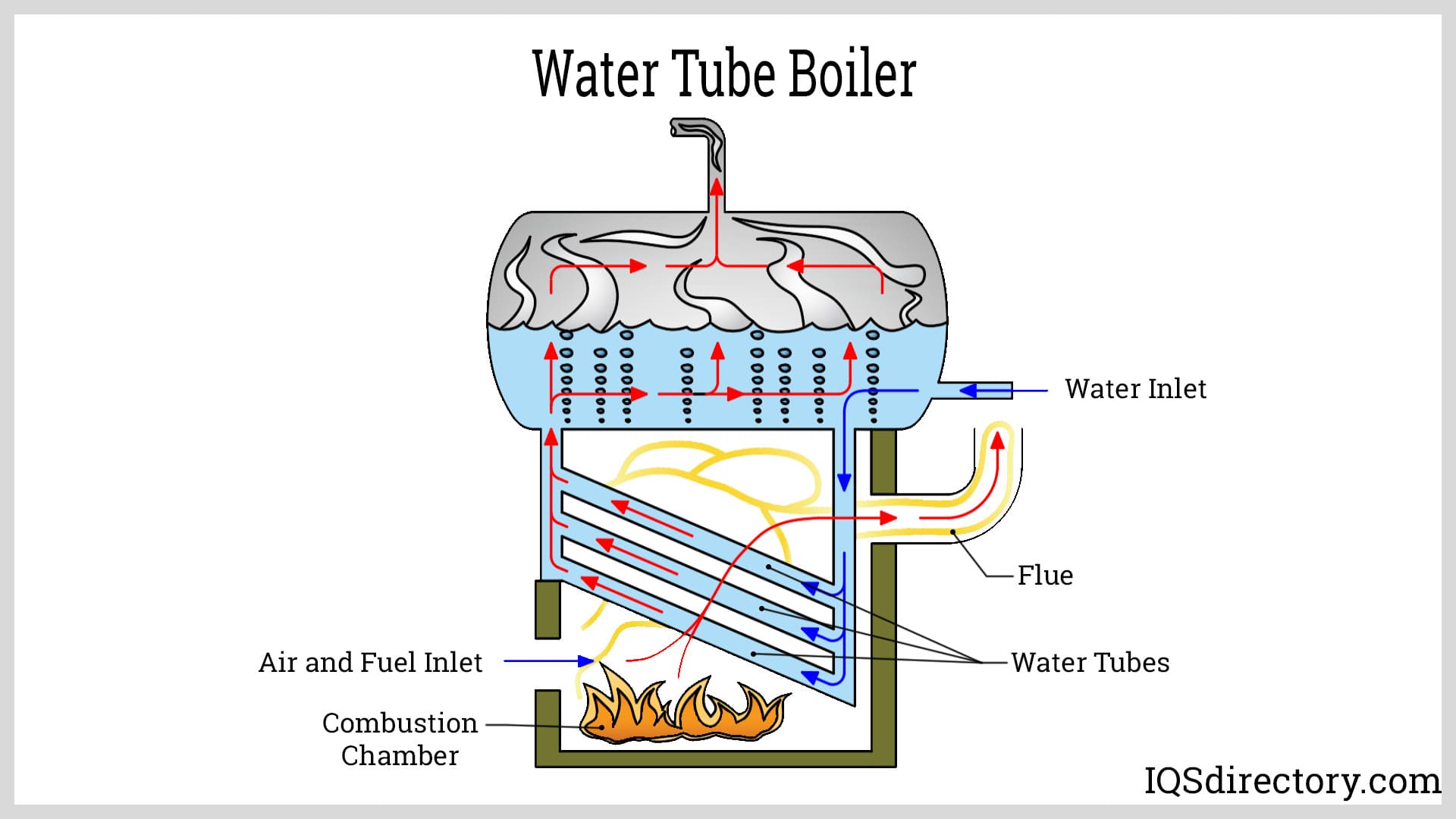

Water tube boilers are a type of steam or hot water boiler where the water flows inside a network of interconnected tubes. These boilers are distinguished from fire tube boilers, where the hot gases from combustion pass through tubes containing the water. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

Bryan Steam has been an industry leading producer of commercial boilers, including their “flexible water tube” model for more than one hundred years. Bryan Steam produces a wide range of gas, oil, dual fuel and electric water and steam options including the ultra-high efficiency Free-Flex models 1000 MBH to 6000 MBH and the BFIT model 1000 MBH to 4000 MBH. Contact the company today for...

At Mid-South Steam Boiler & Engineering Co., we are dedicated to providing top-notch boiler solutions and engineering services tailored to meet the needs of our diverse clientele. With a rich history spanning several decades, we have established ourselves as a trusted authority in the boiler industry, renowned for our commitment to quality, reliability, and customer satisfaction. Our product...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Water Tube Boilers Manufacturers

In water tube boilers, the heat source, often a burner or other combustion system, heats the tubes containing the water, causing it to boil and generate steam or hot water.

Industries That Use Water Tube Boilers

Water tube boilers are used in various industries where steam or hot water is required for various processes. These boilers offer several advantages, including higher efficiency and the ability to handle high-pressure and high-temperature applications. Here are some of the industries that commonly use water tube boilers:

Power Generation: Water tube boilers are widely used in power plants to generate steam for electricity generation. They are often employed in both fossil fuel-based power plants and nuclear power plants.

Petrochemical Industry: Refineries and petrochemical plants use water tube boilers to produce steam for various processes, such as heating, distillation, and chemical reactions.

Chemical Industry: Chemical manufacturing facilities use water tube boilers for processes like chemical synthesis, distillation, and sterilization.

Pulp and Paper Industry: Water tube boilers are used to provide steam for papermaking and pulp production processes, including drying and heating.

Food Processing Industry: Food processing facilities use water tube boilers for tasks like pasteurization, sterilization, and cooking.

Textile Industry: Textile mills require steam for various processes like dyeing, bleaching, and drying, making water tube boilers a common choice.

Pharmaceutical Industry: Pharmaceutical manufacturing relies on water tube boilers for sterilization, distillation, and various heating processes.

HVAC (Heating, Ventilation, and Air Conditioning): Some large-scale HVAC systems and district heating plants use water tube boilers to provide hot water or steam for heating buildings and providing hot water.

Manufacturing and Industrial Facilities: Many manufacturing plants and industrial facilities use water tube boilers for tasks such as heating, steam cleaning, and equipment sterilization.

Marine Industry: Water tube boilers are used in some marine applications, such as on ships and offshore platforms, to provide steam for propulsion and auxiliary systems.

Research and Development: Laboratories and research facilities may use water tube boilers for various research purposes, especially in fields like material science and engineering.

District Heating Systems: Some cities and urban areas use water tube boilers in district heating systems to supply hot water or steam to residential and commercial buildings.

Sugar Industry: Sugar mills often use water tube boilers to produce steam for sugar extraction and processing.

Mining Industry: In mining operations, water tube boilers may be used for various purposes, including providing steam for ore processing and site heating.

Choosing the Right Water Tube Boiler Manufacturer

When choosing a water tube boiler from a water tube boiler manufacturer, it is important to compare at least 4 or 5 manufacturers using our list of water tube boiler manufacturers. Each water tube boiler manufacturer has a business profile page that highlights their areas of experience and capabilities, and has a contact form to directly communicate with the company for more information or request a quote. Review each water tube boiler company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple water tube boiler companies with the same quote.

Choosing the right water tube boiler manufacturer is a crucial decision for any industrial or commercial operation. Water tube boilers are commonly used for various applications, including power generation, heating, and process industries. To ensure you make an informed choice, consider the following factors when selecting a water tube boiler manufacturer:

Experience and Reputation: Look for manufacturers with a proven track record and a long history of manufacturing water tube boilers. Check for references and reviews from previous customers to gauge their reputation in the industry.

Certifications and Compliance: Ensure that the manufacturer complies with industry standards and regulations, such as ASME (American Society of Mechanical Engineers) codes and certifications. Verify that their boilers meet local and national safety and environmental requirements.

Design and Engineering Expertise: Assess the manufacturer's design and engineering capabilities. A reputable manufacturer should have a team of skilled engineers who can design custom solutions to meet your specific needs. Consider whether they offer innovative features or technologies to improve boiler efficiency and performance.

Product Range and Customization: Determine if the manufacturer offers a wide range of boiler types and sizes to meet your capacity and operational requirements. Check if they can customize boilers to suit your unique application and space constraints.

Quality Control and Manufacturing Standards: Inquire about their quality control processes during manufacturing to ensure that the boilers are built to high standards. Ask about the materials used, welding techniques, and testing procedures to guarantee the durability and reliability of their products.

After-Sales Support and Service: Evaluate the manufacturer's commitment to customer support, including maintenance, spare parts availability, and technical assistance. Ensure they have a local or regional service network to provide prompt assistance when needed.

Energy Efficiency and Environmental Considerations: Inquire about the energy efficiency ratings of their boilers and whether they can provide solutions that reduce emissions and environmental impact. Consider whether they offer technologies like economizers, air preheaters, or advanced combustion systems to optimize efficiency.

Warranty and Lifecycle Costs: Review the warranty terms and conditions to understand the coverage and duration. Consider the long-term operating and maintenance costs associated with the boiler, as this can significantly impact your budget.

Financial Stability: Assess the financial stability of the manufacturer to ensure they can support warranty claims and provide ongoing service and support.

References and Site Visits: Request references from other customers who have purchased similar boilers and consider visiting their facilities to see the boilers in operation.

By carefully evaluating these factors, you can make an informed decision when choosing the right water tube boiler manufacturer for your specific needs, ensuring reliability, safety, and efficiency in your industrial or commercial operations.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

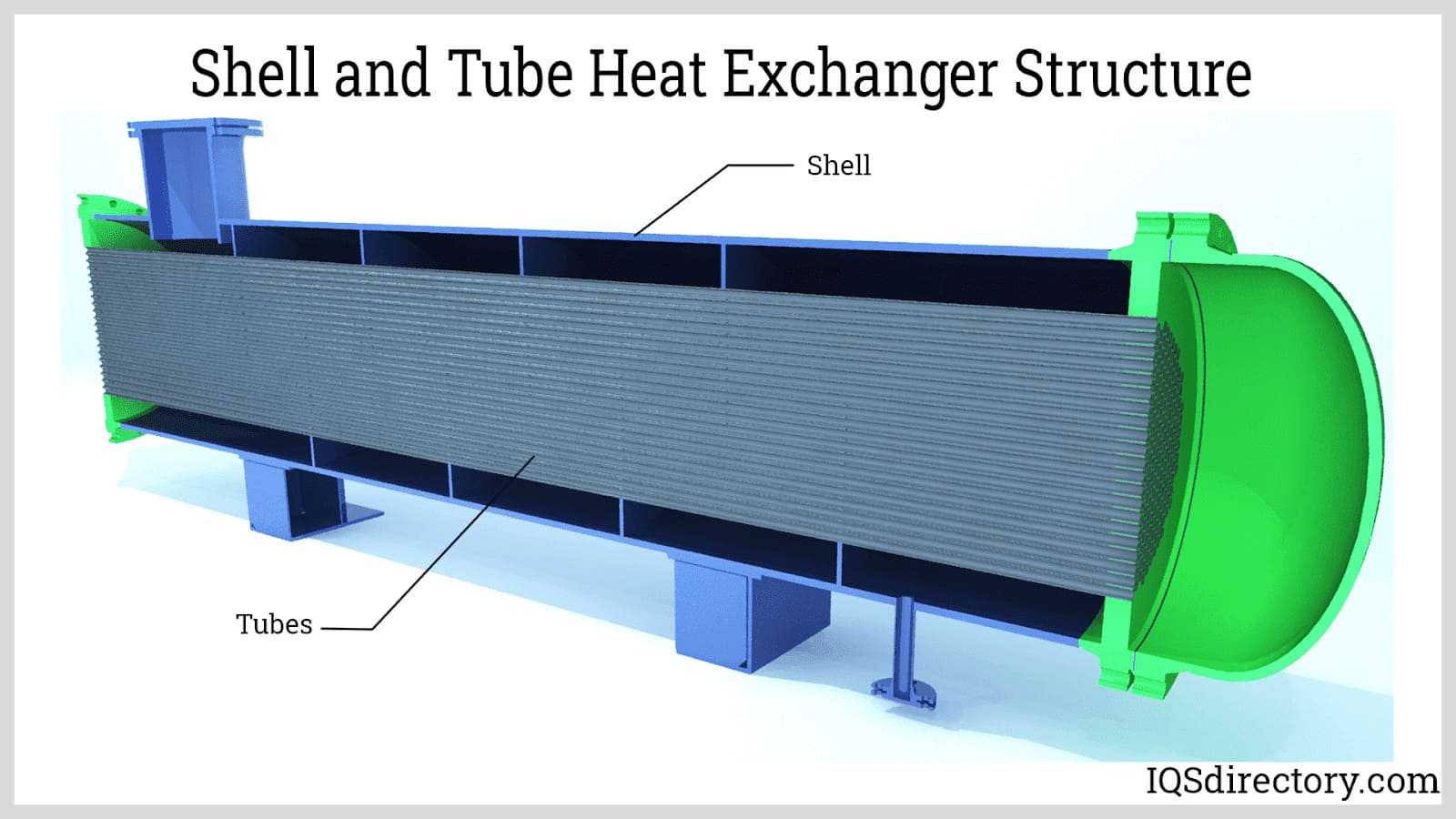

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services