Gas boilers are a popular and effective solution for heating homes and buildings, as well as providing hot water. They work by burning natural gas to produce heat, which is then transferred to the water or air being circulated throughout the building. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

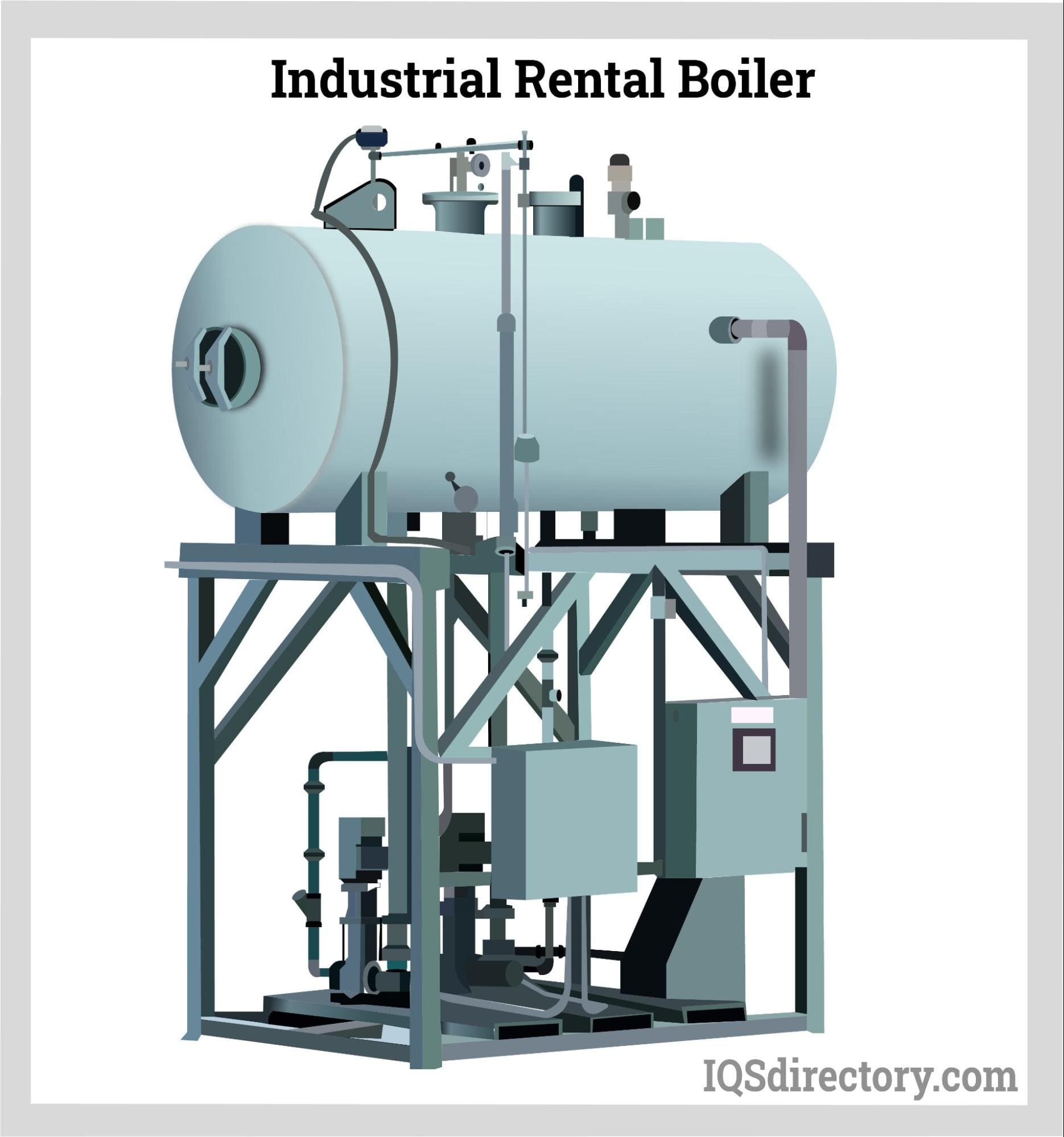

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

Bryan Steam has been an industry leading producer of commercial boilers, including their “flexible water tube” model for more than one hundred years. Bryan Steam produces a wide range of gas, oil, dual fuel and electric water and steam options including the ultra-high efficiency Free-Flex models 1000 MBH to 6000 MBH and the BFIT model 1000 MBH to 4000 MBH. Contact the company today for...

At Mid-South Steam Boiler & Engineering Co., we are dedicated to providing top-notch boiler solutions and engineering services tailored to meet the needs of our diverse clientele. With a rich history spanning several decades, we have established ourselves as a trusted authority in the boiler industry, renowned for our commitment to quality, reliability, and customer satisfaction. Our product...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Gas Boiler Manufacturers

Components of Gas Boilers

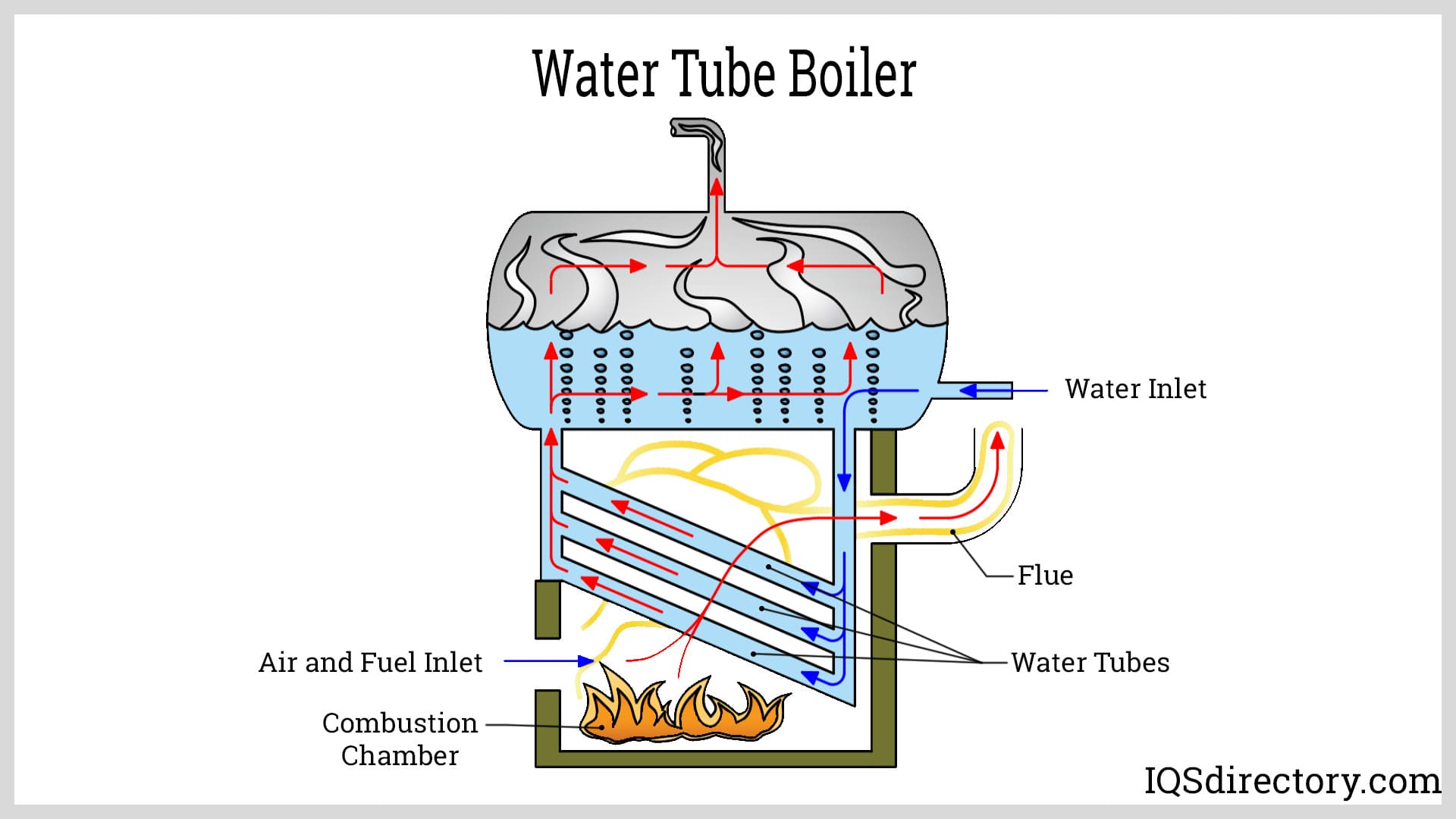

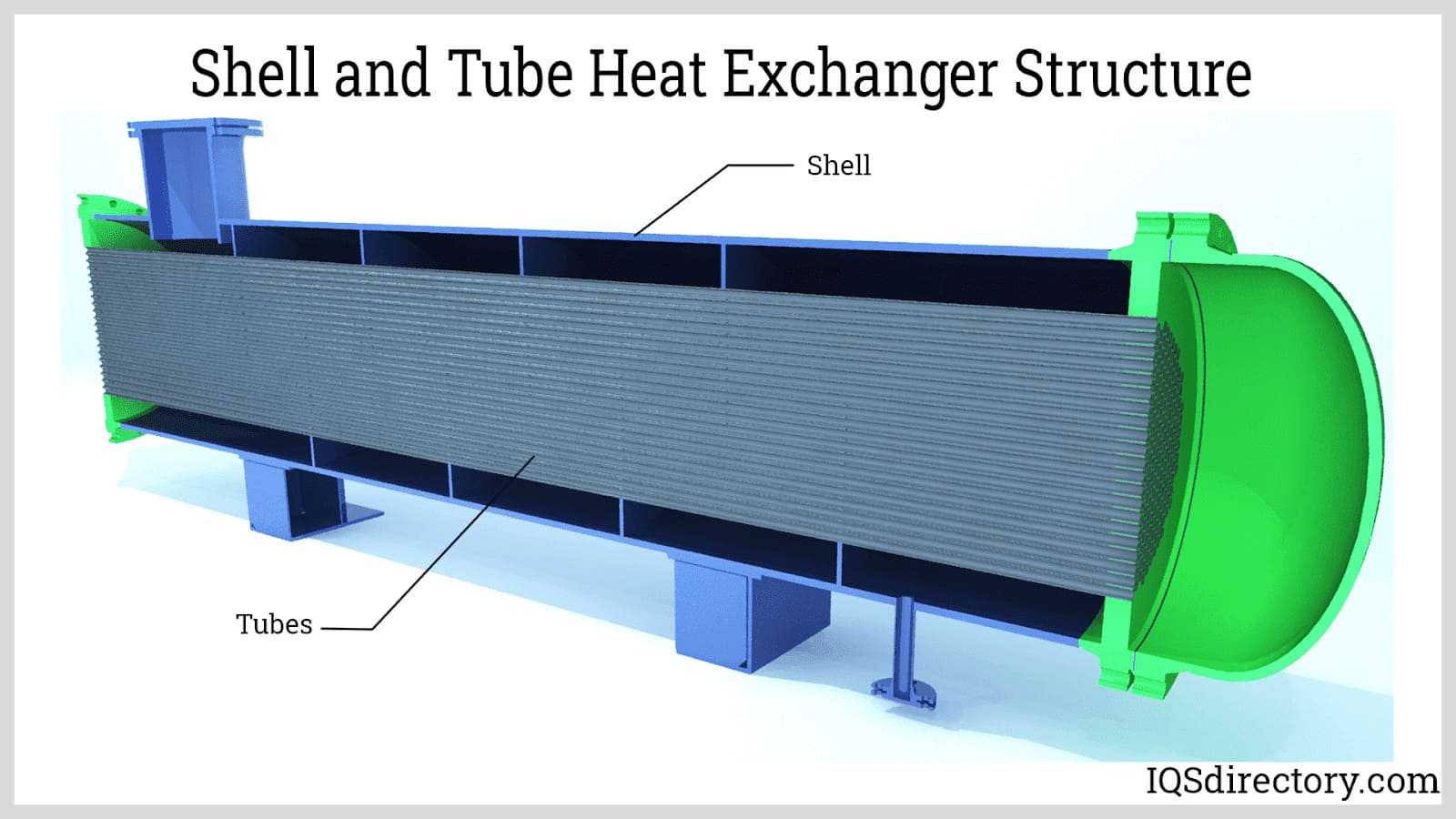

All gas boilers have several common components, including a burner, heat exchanger, expansion tank, circulating pump, and controls. The burner is responsible for igniting the natural gas and producing a flame. The heat exchanger transfers the heat from the burner to the water or air being circulated throughout the building. The expansion tank is used to accommodate any changes in pressure caused by temperature changes. The circulating pump moves the water or air through the system, and the controls regulate the temperature and operation of the boiler.

Types of Gas Boilers

There are three main types of gas boilers: combi boilers, conventional boilers, and system boilers. Combi boilers are compact and provide both hot water and heating, making them popular in small homes or apartments. Conventional boilers are more common in larger homes and provide hot water through a separate cylinder or tank. System boilers are similar to conventional boilers but include additional components, such as a pump and expansion vessel, to make installation easier.

System boilers and conventional boilers can both serve larger buildings, but the main difference between them is how they store and distribute hot water. Conventional boilers heat water in a separate hot water cylinder or tank, which is typically located in an airing cupboard or loft. The hot water is then distributed throughout the building through the use of gravity or a pump. System boilers, on the other hand, store hot water within the unit itself, and do not require a separate hot water cylinder. They typically have an internal circulating pump and expansion vessel, which allows them to distribute hot water at a higher pressure than conventional boilers.

So, while both types of boilers can be used for larger buildings, system boilers may be more efficient and easier to install since they do not require an additional hot water cylinder. However, the choice between a system boiler and a conventional boiler will ultimately depend on the specific heating and hot water requirements of the building or area being served.

Considerations Regarding Gas Boilers

There are several considerations to be aware of when using gas boilers. Carbon monoxide poisoning can be a risk if the boiler is not properly installed, maintained, and ventilated. Meanwhile, the installation and maintenance costs can be high, especially compared to electric heating solutions. Additionally, the environmental impact of burning natural gas can also be a concern for some individuals.

Benefits of Gas Boilers

Despite these considerations, there are several benefits to using gas boilers. They are highly efficient, which can result in significant cost savings on heating bills compared to other options, including electric. Likewise, they are also reliable and durable, with a longer lifespan than many other heating solutions. Additionally, gas boilers are compatible with renewable energy sources, such as solar panels or wind turbines.

Applications of Gas Boilers

Gas boilers are versatile heating appliances that can be used in a wide range of applications. Here are some of the most common applications of gas boilers:

Residential Heating

Gas boilers are commonly used in homes to provide central heating and hot water. They can be used in combination with radiators, underfloor heating systems, or even heat pumps to provide efficient and reliable heating solutions for homes of all sizes.

Commercial Heating

Gas boilers are widely used in commercial buildings, such as offices, schools, hospitals, and hotels, to provide heating and hot water. They are particularly well-suited to larger buildings with high heating demands, and can be used in conjunction with other heating systems, such as air conditioning or ventilation, to provide a complete heating and cooling solution.

Industrial Heating

Gas boilers are also used in industrial settings, such as factories and warehouses, to provide process heat for manufacturing processes. They can be used to heat water, steam, or other fluids to specific temperatures, and can be designed to meet the unique heating requirements of each individual application.

District Heating

Gas boilers can be used in district heating systems to supply heating and hot water to multiple buildings in a local area. This type of system is particularly popular in urban areas, where a large number of buildings can be served by a single central heating plant.

Power Generation

Gas boilers can also be used in power generation applications, where they are used to heat water and produce steam to drive turbines and generate electricity. Gas-fired power plants are generally more efficient and emit fewer greenhouse gasses than coal-fired power plants, making them a cleaner and more environmentally-friendly choice for electricity generation.

Choosing the Proper Gas Boiler Manufacturer

To ensure you have the most beneficial outcome when purchasing a gas boiler from a gas boiler manufacturer, it is important to compare several companies using our directory of gas boiler manufacturers. Each gas boiler manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each gas boiler business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple gas boiler companies with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services