Cleaver-Brooks

Cleaver-BrooksRequest A Quote

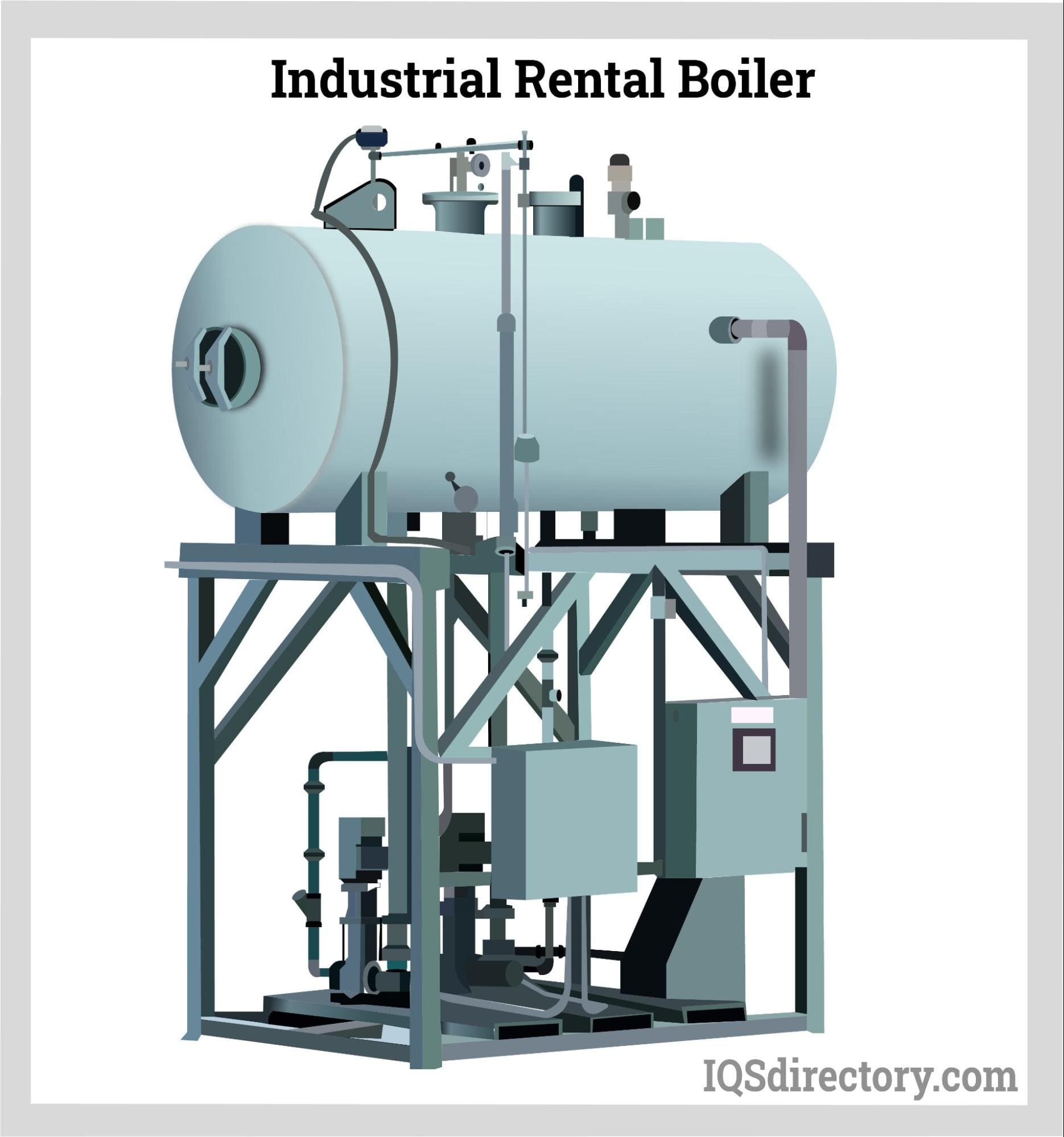

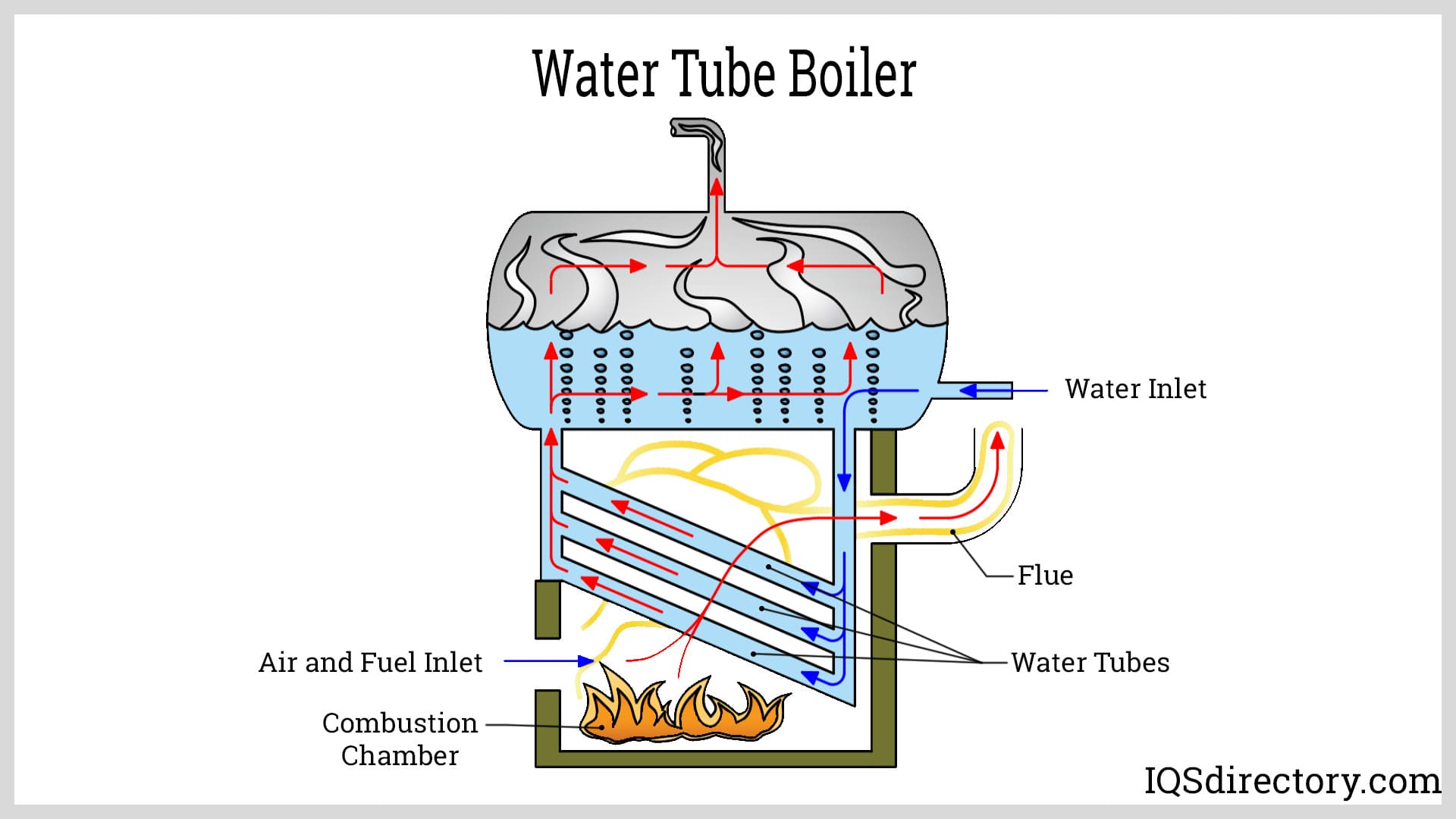

Thomasville, GACleaver-Brooks is a globally recognized leader in the design, manufacturing, and servicing of industrial boiler systems. With a history spanning over 90 years, Cleaver-Brooks has built a strong reputation for delivering innovative, reliable, and energy-efficient boiler solutions for a wide range of industries. At the core of Cleaver-Brooks' product portfolio are their cutting-edge industrial boilers. They offer a comprehensive range of boiler types, including firetube boilers, watertube boilers, electric boilers, and condensing boilers. These boilers are engineered to provide superior performance, efficiency, and reliability in demanding industrial applications such as manufacturing, power generation, oil and gas, healthcare, and more. Cleaver-Brooks' industrial boilers are designed with a focus on energy efficiency and emissions reduction. They incorporate advanced combustion systems, integrated control technologies, and heat recovery options to optimize fuel utilization and minimize environmental impact. By maximizing energy efficiency, Cleaver-Brooks helps their customers reduce operating costs and meet sustainability goals. In addition to their high-quality boiler systems, Cleaver-Brooks offers comprehensive service capabilities to support their customers throughout the entire lifecycle of their boiler systems. Their team of experienced technicians and engineers provides a range of services, including installation, commissioning, preventive maintenance, repairs, and retrofits. These services are designed to ensure that the boilers operate at peak performance, maximizing uptime and productivity for their clients. Cleaver-Brooks' service offerings also include remote monitoring and diagnostics, enabling proactive maintenance and efficient troubleshooting. Through their innovative Cleaver-Brooks' Boiler Management System (BMS), customers can monitor and optimize boiler performance, track energy consumption, and access real-time data for informed decision-making. This advanced technology allows for predictive maintenance and helps prevent potential issues, minimizing downtime and reducing overall operating costs. Furthermore, Cleaver-Brooks is committed to providing exceptional customer support. Their dedicated customer service team is available 24/7 to address inquiries, provide technical assistance, and offer expert guidance. Whether customers need assistance with troubleshooting, parts replacement, or general inquiries, Cleaver-Brooks' knowledgeable staff ensures prompt and reliable support. Cleaver-Brooks' commitment to quality is evident in their rigorous manufacturing processes and adherence to industry standards. Their state-of-the-art manufacturing facilities utilize advanced technologies and robust quality control measures to ensure that every boiler system meets or exceeds the highest standards for performance and reliability. Cleaver-Brooks holds various certifications, including ISO 9001, ASME, UL, and CSA, further validating their commitment to excellence. With a global presence, Cleaver-Brooks serves customers across multiple industries and geographies. Their strong distribution network and extensive sales and service locations ensure that customers receive responsive support and timely delivery of products and services. Cleaver-Brooks' technical expertise, industry knowledge, and customer-centric approach have made them a trusted partner for businesses seeking reliable and efficient industrial boiler solutions. In summary, Cleaver-Brooks is a leading provider of industrial boiler systems, offering a wide range of high-quality products and comprehensive services. Their focus on energy efficiency, emissions reduction, and customer satisfaction sets them apart in the market. With their advanced technologies, experienced team, and commitment to excellence, Cleaver-Brooks is the ideal partner for businesses seeking reliable, sustainable, and cost-effective industrial boiler solutions.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

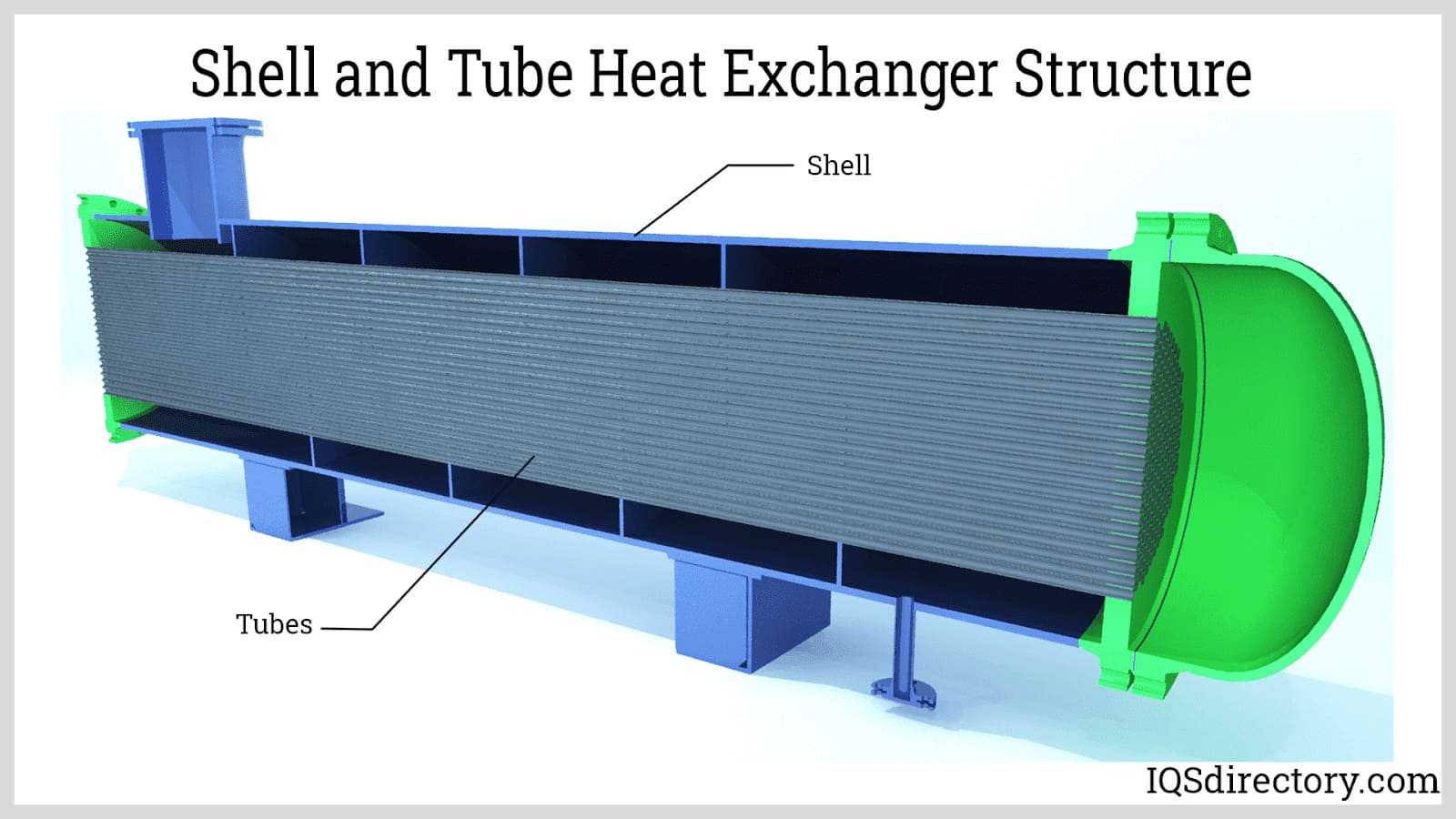

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services