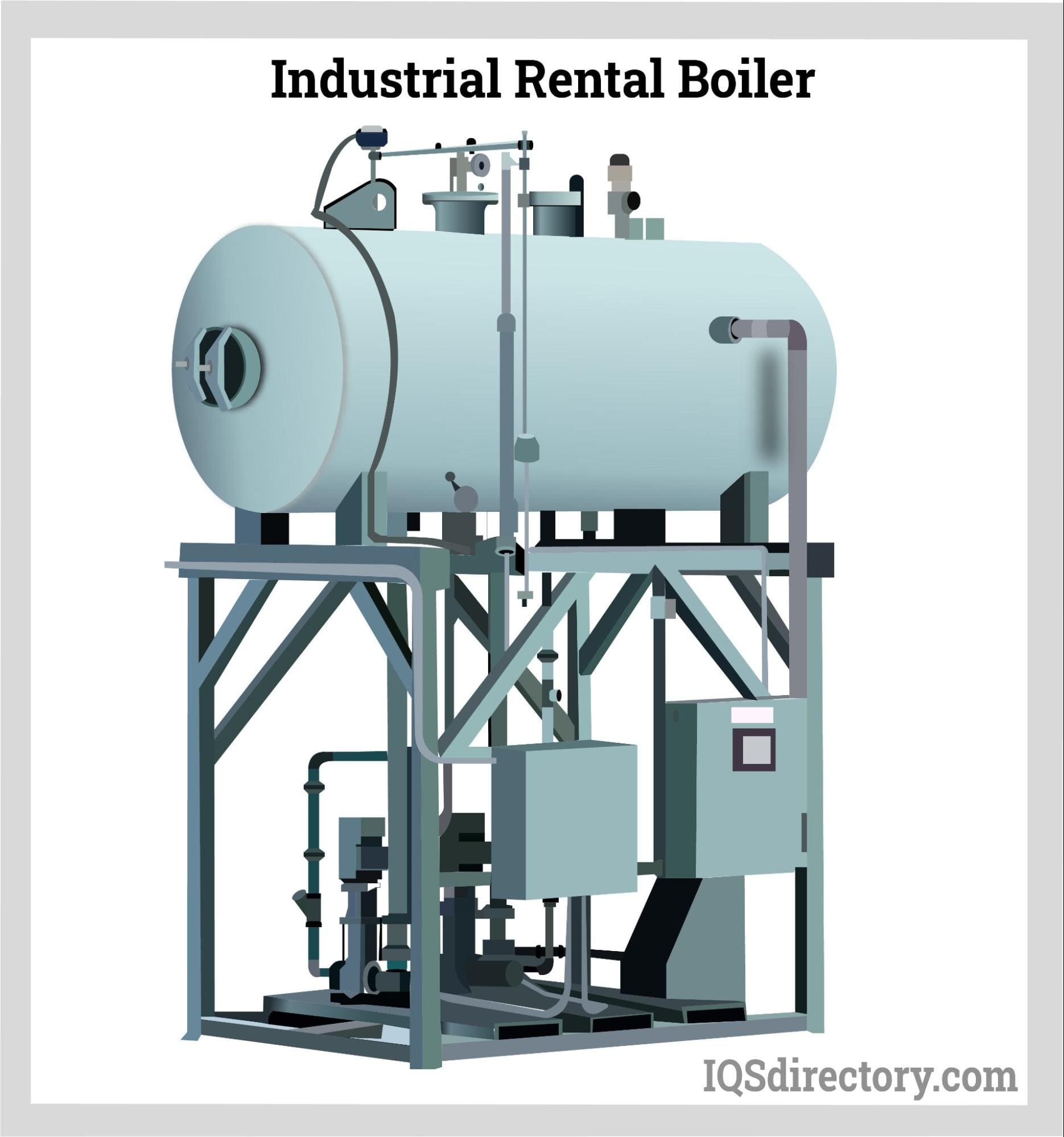

Industrial boilers are closed vessels that use an external fuel source to heat water or another liquid held within and transform these liquids into a larger source of energy. This energy results from the increased pressure water endures while heated in a confined space. Read More…

We strive for the best at Unilux Advanced Manufacturing LLC. Our boilers are designed with superior materials. We are proud to say that we produced the world's first UL/FE boiler and our units provide the highest levels of safety and accountability.

As the inventor of the vertical tubeless boiler, Fulton has a reputation for success dating back to 1949. We`re a global manufacturer of steam, hot water and hydronic boilers, thermal fluid heaters, and custom engineered systems.

Miura Boiler Co., Ltd. has been manufacturing, designing, engineering and servicing gas, oil, coal, wood, solid waste, biomass & hybrid fuel-fired steam & gas and condensing since our inception. With installations across all industries worldwide, We are recognized for the highest code standards, innovative engineering and design, Energy Star rating, fully Integrated controls, and renewable,...

Indeck has the largest inventory of steam generating systems, a custom boiler design team and our own boiler manufacturing plant . Indeck is the complete steam power solution provider with emergency rental of 25,000 pph trailer-mounted rental boilers to the design of large custom million pound boilers. Our expertise includes watertube, mobile, packaged, waste heat, solid fuel, biomass and fire...

Bryan Steam has been an industry leading producer of commercial boilers, including their “flexible water tube” model for more than one hundred years. Bryan Steam produces a wide range of gas, oil, dual fuel and electric water and steam options including the ultra-high efficiency Free-Flex models 1000 MBH to 6000 MBH and the BFIT model 1000 MBH to 4000 MBH. Contact the company today for...

At Mid-South Steam Boiler & Engineering Co., we are dedicated to providing top-notch boiler solutions and engineering services tailored to meet the needs of our diverse clientele. With a rich history spanning several decades, we have established ourselves as a trusted authority in the boiler industry, renowned for our commitment to quality, reliability, and customer satisfaction. Our product...

Nationwide Boiler is a leading supplier of new and reconditioned boilers for industrial facilities worldwide. We’re a manufacturer’s representative and stocking distributor for B&W package watertube boilers and Superior package firetube boilers, and we have fully reconditioned boilers in a variety of types and sizes. With sales, service and equipment depots throughout the U.S., we strive to...

More Industrial Boiler Manufacturers

There are two types of industrial boilers: steam boilers and hot-water boilers. In steam boilers, water is heated to the point where steam forms. This steam is then directly transferred through a series of tubes as an energy source to power equipment, or generate electricity. Hot water boilers, meanwhile, use a series of pumps to direct heat throughout a system in order to achieve similar results. Regardless of which type of industrial boiler is used, they provide businesses with an affordable option to run their operations.

Components of Industrial Boilers

Obviously, any mechanism that can create an energy source from water will be fairly complex. Industrial boilers, for example, include a variety of components including pumps, control mechanisms, supply lines, and return lines. Below, we examine the core components of an industrial boiler.

The Burner: The burner starts the combustion reaction inside the boiler. Fuel is pumped into the burner and, when the burner receives the appropriate signal, the fuel is ignited.

Combustion Chamber: The combustion chamber is usually constructed of cast iron or steel and may reach temperatures of several hundred degrees in a matter of minutes. It produces heat by burning this external fuel source and transferring it to the heat exchanger.

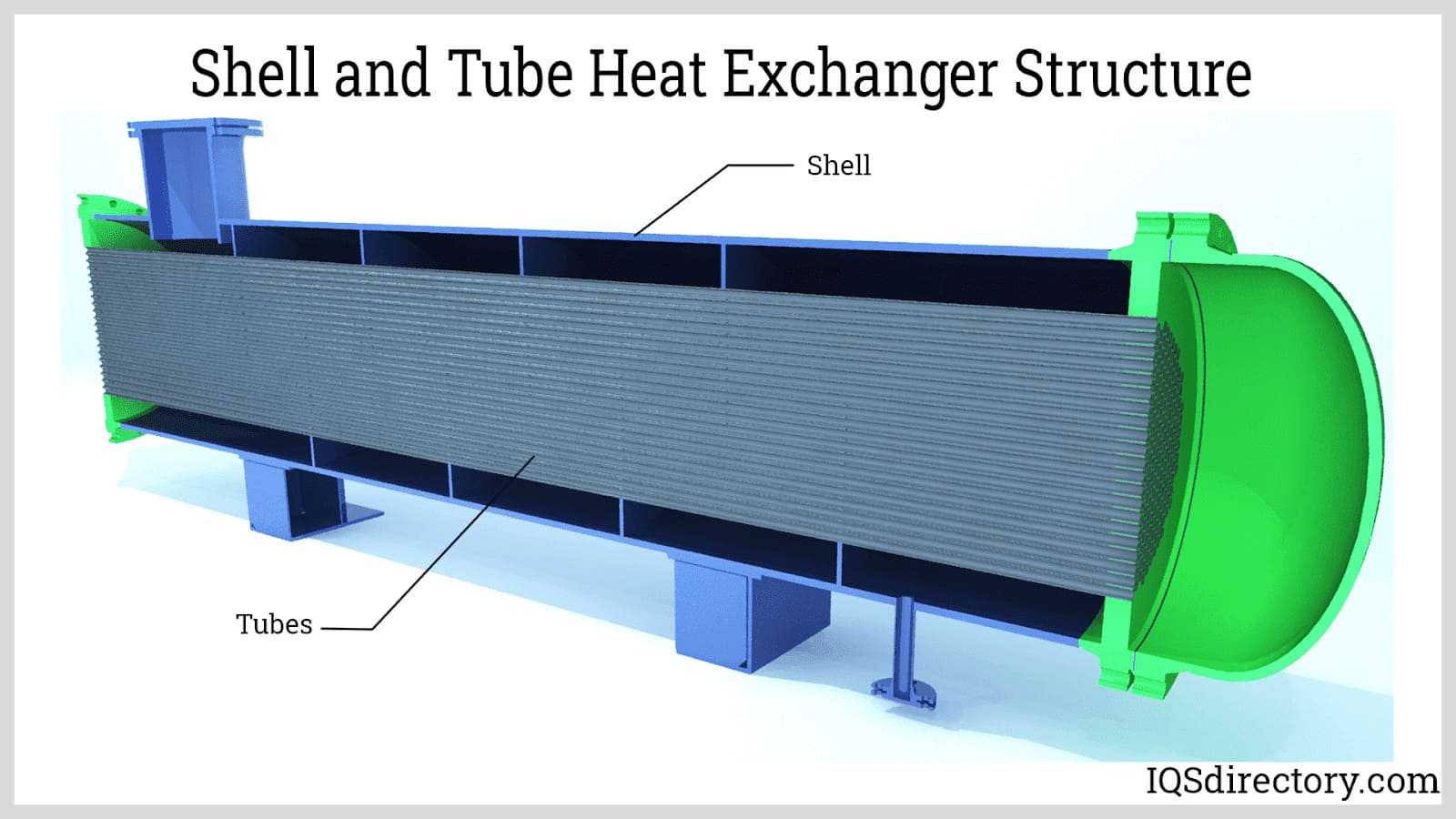

Heat Exchanger: The heat exchanger is where the water is heated and is pumped elsewhere or where steam is created.

Industrial boilers may also contain steam drums and mud drums. Steam drums collect the steam, while a mud drum is positioned beneath the steam drum and gathers any solid that may form during the heating process. Mud drums allow this material to be periodically removed.

Fuel sources for boilers range from coal and kerosene to natural gasses.

Types of Industrial Boilers

Electric Boilers

Electric boilers are the most widely used kind of boiler. These boilers are extremely effective and are considered environmentally-friendly since they don’t directly use fossil fuels as a heat source and, unlike conventional boilers, electrical boilers produce no exhaust fumes.

Electrical boilers are less expensive to install, take up less space, and are much quieter to install than other industrial boilers since they use electricity and don’t have to produce an energy source on their own. Despite appearing to be the most advantageous, electric boilers nevertheless contain drawbacks. They use a lot of electricity and electricity is not as economical as many other energy sources.

Fire Tube Boilers

Fire tube boilers use a series of tubes to direct heat from the heat exchanger through the water held in an industrial boiler. Fire tube boilers are used by a large number of small- and medium-sized businesses. They are ready to begin operating once they are linked to a fuel and water source because they are factory-made and equipped with pumps and control systems. They're frequently referred to as packed boilers.

These boilers are appropriate for low- to medium-pressure steam needs. Although they have a comparatively high risk of explosion, fire tube boilers can also produce steam with a pressure of up to 2000 boiler horsepower (1 BPH = 34.5 pounds of steam generated per hour). Fire tube boilers can be an expensive means of creating power for businesses that don’t otherwise use steam energy in their facility.

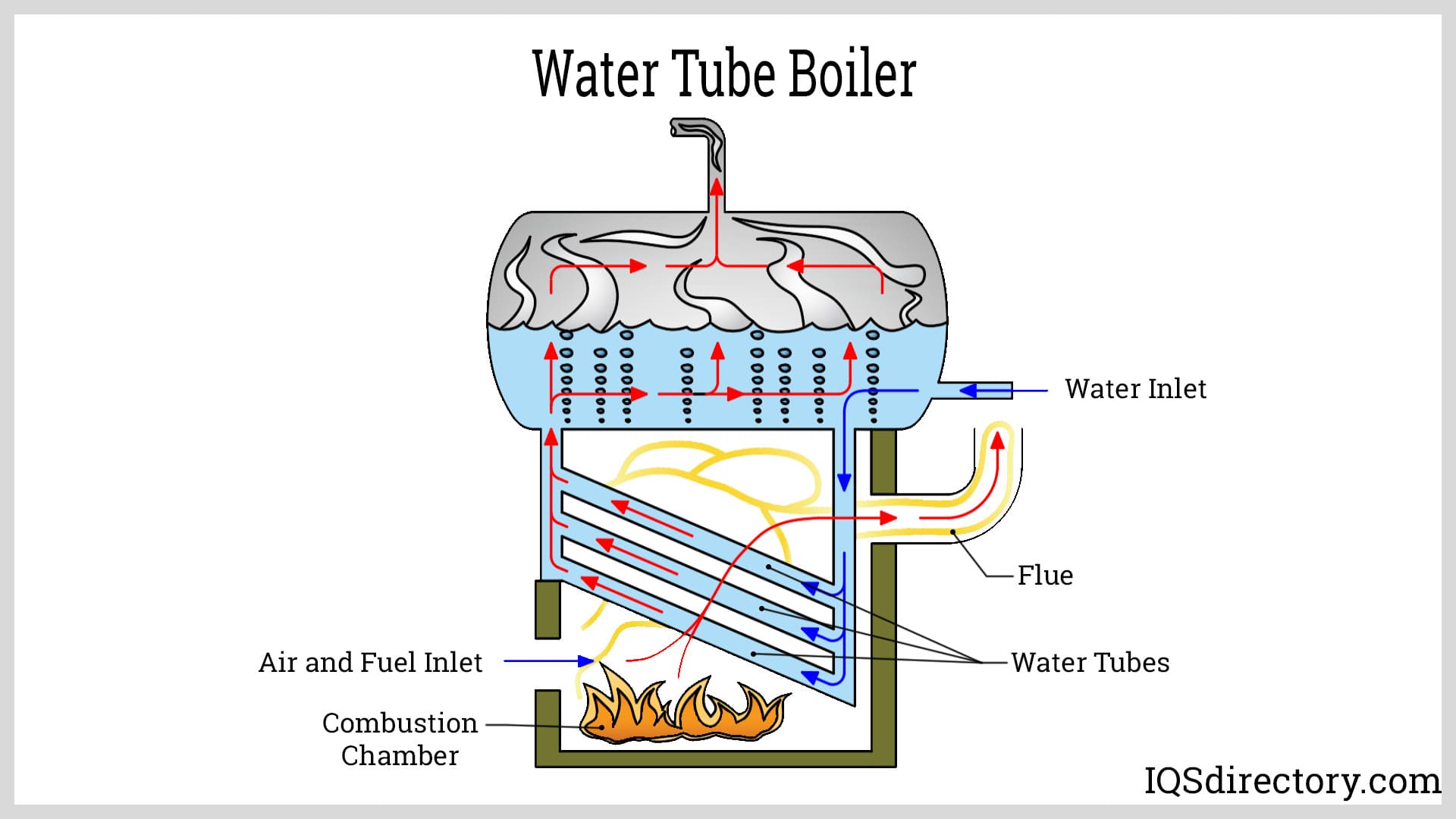

Water Tube Boilers

Water tube boilers differ from fire tube boilers in how they are designed and, subsequently, how they heat water. Whereas the water essentially surrounds the heat source in a fire tube boiler, the water is surrounded by the heat source in a water tube boiler. Water tube boilers contain tubes that allow the water to run to the center of the boiler. This design allows for more efficient heating and requires less fuel when compared to a fire tube boiler.

Water tube boilers are typically employed in large manufacturing facilities. Water drum boilers allow a user greater control over water circulation than fire tube boilers and are ideal if a user needs to regularly modify steam quantity. Water tube boilers are not typically offered as packaged units and are frequently manufactured on-site.

Natural Gas Boilers

Natural gas boilers, as the name implies, burn natural gas as their fuel. The gas heats the boiler's coils after the pilot is lit. Like other modern boilers, today’s natural gas boilers use a thermostat and series of pressure and temperature switches to control and maintain temperature. Propane gas is regularly used as a substitute fuel source in rural areas where natural gas pipelines do not run.

Oil Boilers

Here, oil is used as fuel rather than natural gas. Oil-fired boilers typically have an efficiency of 86%.

Condensing Boilers

Condensing boilers operate differently than other industrial boilers. Condensing boilers are powered by two two heat sources. Condensing boilers are powered primarily by natural gas. However, condensing boilers are also able to capture the heat that is normally vented outside other boilers during the combustion process and redirect this heat as a secondary source of warmth. This boiler is the most environmentally-friendly and most fuel-efficient because it has two heat sources that reduce waste and costs.

Industrial Applications of Industrial Boilers

Agriculture

Industrial boilers serve numerous agricultural applications. They are used as a source for generating hot water and steam to the various buildings that may be found on a farming complex. Furthermore, the steam is used to sterilize various instruments and pieces of equipment.

Steam is also used in a process known as soil sterilization. Under this procedure, weeds, germs, viruses, and fungi are all killed by applying steam to soil. Killing soil bacteria also results in the release of cellular proteins, significantly boosting the soil's nutrient content. However, spore-forming bacteria are heat-resistant and can live or reactivate once the soil is returned to its cold state. Hence the technique is considered to be just a partial disinfection. The process of steam sterilization can be done outdoors or in greenhouses.

Hospitals

Hospitals use the steam produced from industrial boilers for sterilizing operating rooms, and equipment. Industrial boilers are used to heat hospital buildings. Industrial boilers also serve in the sanitation of laundry, food preparation equipment, and dining utensils and plates.

and Elsewhere…

Since industrial boilers can generate electricity, their applications are nearly limitless.

Choosing the Right Industrial Boilers Supplier

To make sure you have the most beneficial outcome when purchasing Industrial Boilers from an Industrial Boilers Company, it is important to compare at least 5 or 6 Suppliers using our list of Industrial Boilers suppliers. Each Industrial Boilers Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Industrial Boilers business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Industrial Boilers businesses with the same quote.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services